With the growth of industrial AI and the IoT, Organisations in most of the sectors are being reimagined through software. Businesses are learning how to utilize their information to not just examine the past but forecast the future too.

Maintenance is a vital area that may drive significant cost savings and manufacturing value across the globe. Even the expense of machine downtime is substantial: As stated by the International Society of Automation, $647 billion has been lost worldwide annually.

During this time organizations have unacted maintenance procedures to facilitate downtime and increase effectiveness. There seems to be more confusion, but yet, across the ideal approach to make use of statistics of data from the pursuit for optimal functional efficiency.

Together with AI and ML, we’ve got the capability to process enormous quantities of sensor data quicker than before. This provides organizations an unparalleled opportunity to increase upon existing maintenance operations and add something new: predictive maintenance.

One sector that could see outstanding savings from AI is manufacturing. When most manufacturers already are utilizing some sort of preventive or predictive maintenance, AI could usher in a brand new age of expansion. You may be wondering that how can data, machine learning, and AI belong to the present maintenance system I am currently using? Let us break a couple of common maintenance types along with their function AI performs in each.

Artificial Intelligence’s Role in Total Productive Maintenance

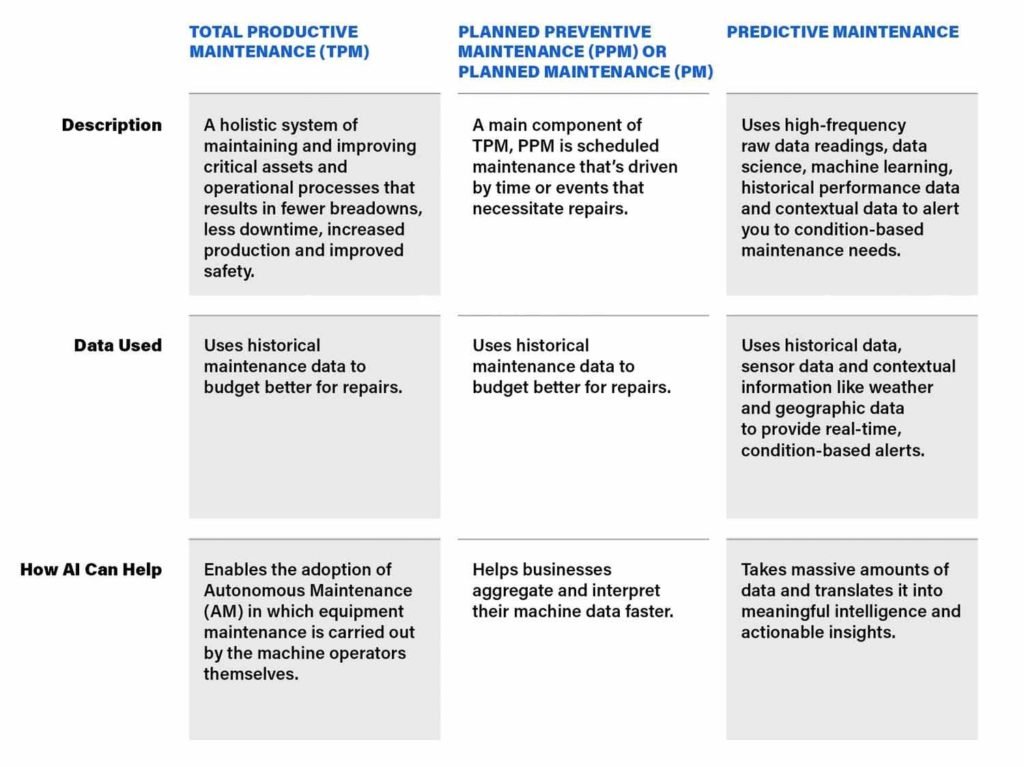

Total Productive Maintenance (TPM) is a holistic approach to improving and maintaining critical assets and operational procedures which result in fewer disputes, less downtime, higher production, and enhanced protection.

Manufactured in the 1960s, most industrial businesses have now started utilizing this procedure now to effectively complete system maintenance predicated upon historic statistics of data and time tables of when repairing has been required to become.

With theories of proposed routine maintenance, TPM intends to enhance Overall Equipment Effectiveness (OEE) and plant growth. With routine equipment servicing, you’ll be able to stay away from breakdowns and boost the bandwidth of assets.

Artificial Intelligence along with Autonomous Maintenance Adoption and Implementation

Certainly one of those center functions of TPM is Autonomous Maintenance (AM). Such type of maintenance makes everybody accountable for system performance and upkeep. Equipment servicing is performed by the system operators, in the place of maintenance technicians being the sole ones to repair assets.

By having machine operators do routine maintenance in assets, technicians have been now freed up to concentrate on bigger adjustments to enhance overall system efficiency. AM can be hard to execute as it normally requires a good deal of communicating and also training. Device operator’s deficiency the historic system data technicians possess, and also technicians may perhaps not be quite as fast to quit certain jobs without foresight into new job duties coming.

Today, Companies are able to benefit from AI-driven applications which makes adoption of Autonomous Maintenance much easier. Operators around the front line may know their machinery much better compared too previously.

Possessing your entire historic information in one single easy-to-access dashboard keeps everybody on the same page also makes it much easier for machines to become vaccinated, quicker. Nowadays, businesses can guarantee that all proprietor gets the proper tools as well as the proper knowledge in the most suitable time to finish the work.

Differentiation between Planned Preventive Maintenance vs. Predictive Maintenance

Planned Preventive Maintenance (PPM), is servicing that’s pushed by events or time which require repair. A major part of TPM, such type of system ensures routine maintenance is scheduled while some machines are working as a way to stop unplanned downtime and also optimize the life and efficiency of the equipment. Although powerful, there are particular drawbacks for the particular method. It isn’t an exact science, you run the risk of over-maintaining or even under-maintaining your own assets, plus it depends upon parameters to get regular assessments but does not take into consideration contextual information.

Predictive Maintenance utilizes condition-based signs and notifications to routine maintenance demands just if your trucks are in danger of breaking down – optimizing your own servicing cadence and optimizing vehicle availability. As an instance, a car will notify you if the engine is at risk of overheating out the planned maintenance program. Such maintenance is performed in case your vehicles are still working but at a high chance of failure.

Data and Artificial Intelligence in Preventive and Predictive Maintenance

As data and connectivity accessibility become cheaper and more widespread in the industry, numerous companies are looking to predictive servicing, or condition-based, maintenance, powered by machine learning and analytics.

PPM is primarily driven by time-based data. For instance, on a car, maintenance is determined by exactly the period of mileage or time passed compelled to establish when maintenance needs to be carried out. This data additionally contrasts exactly how a particular asset is working than the other of one’s like assets. Statistics only informs you exactly what could occur. Most maintenance technologies revolve around distributing information, maybe not aggregating it to data that is real-time. But delivering the information is only the very first step – what you can do with all this information is that which really matters. Artificial Intelligence and machine learning can help aggregate and make utilization of your data, quicker.

Predictive maintenance utilizes information from several sources such as historic servicing records, sensor data in the machines, and climate data to figure out every time a machine needs to get serviced. Using real-time asset data plus historical statistics, operators may make more correct decisions about every time a machine will demand a repair. Preventative Servicing takes an enormous amount of information and throughout using AI and Preventive maintenance software, translates that information into meaningful data and insights points – helping you to avoid information overload.

Sensor information and machine learning units will be getting it feasible to rapidly extract more value out of enormous quantities of cluttered data. Predictive maintenance software updates your current maintenance processes using AI to make sure that your folks have the proper knowledge and resources to keep your mission-critical assets running at peak performance.

Summary: AI’s Function in bettering Routine Maintenance Softwares and Processes

The inherent secret to effectively executing maintenance operations which truly meet your Company’s demands is knowing exactly what requirements that you want answers to and also how information may help get these answers.

Do you want to understand what has already occurred so that you may budget and plan for the next year? Or do you want to find out how to exactly stop unplanned downtime, reduce expenses and expedite repairs?

Since digitization continues to change organizations, optimizing your operations and Implementing maybe not just preventative maintenance, but predictive maintenance applications too, has turned into table-stakes to live. Tech isn’t just a luxury anymore, it’s necessary to continue being competitive and minimize downtime, enhance security and revenue.